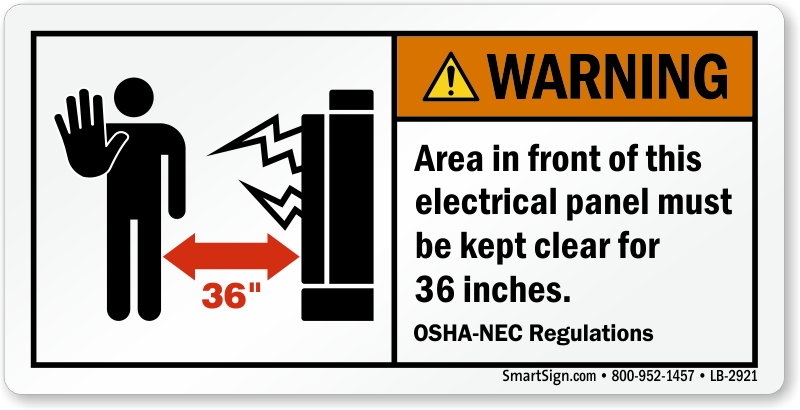

Osha requirements stipulate that electrical panels must be accessible at all times for routine maintenance inspection or emergency service.

Osha electrical panel clearance diagram.

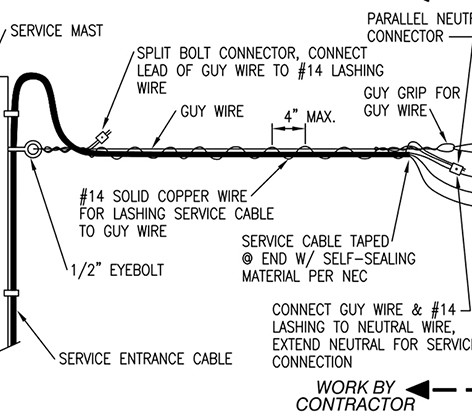

This is generally done via clamping a system ground wire to a metal cold water pipe or to ground rods driven into the earth.

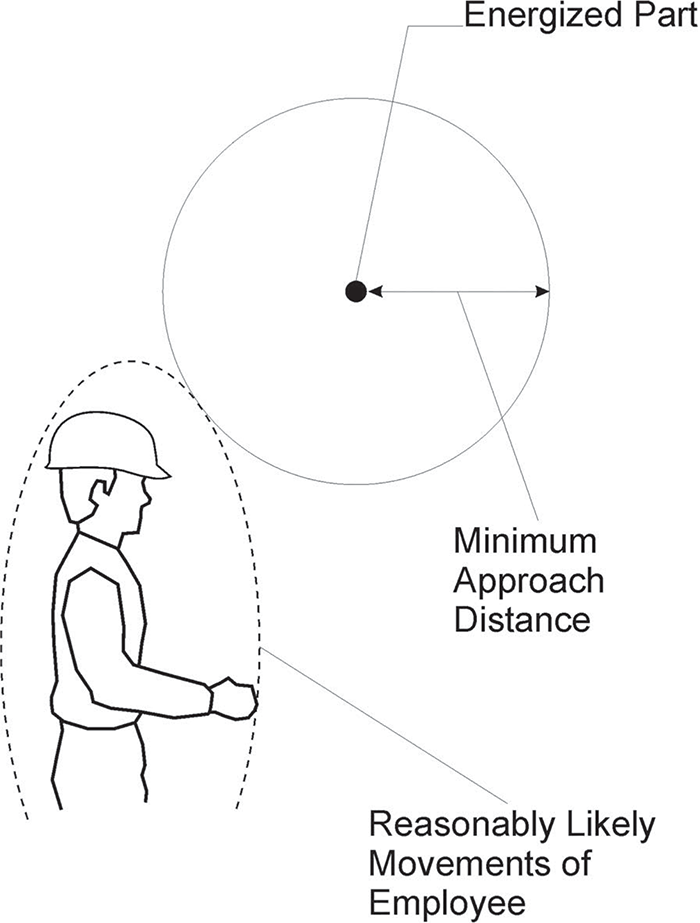

Osha 29 cfr 1910 333.

In order to be compliant with osha clearance requirements relating to electrical panels space in front of the panel must be 30 wide or the width of the panel.

A clearance of at least 3 feet is required for equipment using 120 to 250 volts.

Shock results when the body becomes part of the electrical circuit.

The steel electrical panel is then connected to the earth.

Electrical shock is defined as a reflex response to the passage of electric current through the body.

According to the osha standard 29 cfr 1910 303 g companies are required to provide 3 feet of clearance around electrical services and breaker panels with between 120 and 250 volts.

Condition a exposed live parts on one side and no live or grounded parts on the other side of.

Insufficient clearance around electrical panels is one of the many electrical hazards that can endanger worker safety.

The working width around the panel must be at least 30 inches.

Clearance around an indoor electrical panel nec 110 26 clearance for conductor entering in panel nes 408 5 clearance between bare metal busbar in panel nes 408 5 clearance of outdoor electrical panel to fence wall nes 110 31 working space around indoor panel circuit board nes 110 34 clearance around an outdoor electrical panel nes.

Reflex response to passage of electric current through the body.

Includes references that provide information related to electrical in construction including osha s electrical construction regulations hazard recogition possible solutions and additional resources.

To ensure that an electrical panel can be accessed at all times during inspection maintenance or emergency osha has determined that the working space in front of the equipment must be at least 30 inches wide or the width of the equipment.

Equipment grounding only works when there is a permanent and continuous electrical connection between the metal shell of a tool and the earth.

Examination adjustment servicing maintenance.

1 minimum depth of clear working space in front of electric equipment with a nominal voltage to ground above 25 000 volts may be the same as that for 25 000 volts under conditions a b and c for installations built before april 16 1981.

Notes to table s 2.

Obstructed access to panelboards can prevent personnel from shutting down the source of power in the event of an accident.

2 conditions a b and c are as follows.

In addition to osha standards electrical panels fall under national electrical code nec.